Working process of drilling fluid sand pump

The sand pump for drilling fluid is one of the important equipment in drilling solid control equipment. Its main function is to provide drilling fluid with a certain pressure and flow rate for sand remover, desilter, and jet mud mixer. Currently, the sand pumps used on drilling sites are large-capac

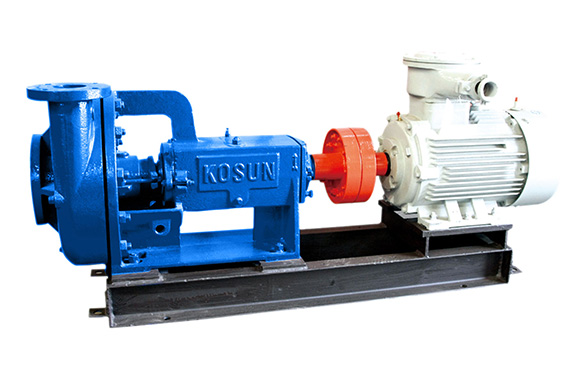

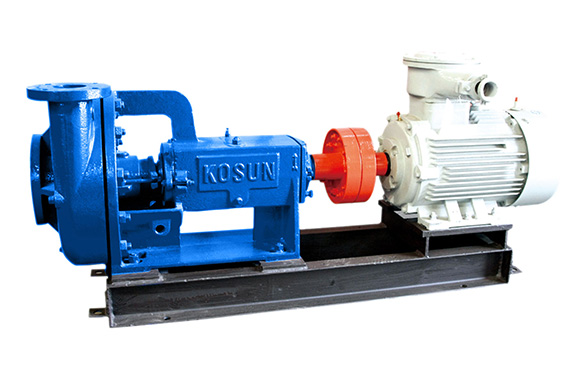

The sand pump for drilling fluid is one of the important equipment in drilling solid control equipment. Its main function is to provide drilling fluid with a certain pressure and flow rate for sand remover, desilter, and jet mud mixer. Currently, the sand pumps used on drilling sites are large-capacity centrifugal pumps, which can be divided into horizontal sand pumps and vertical sand pumps according to their structural forms.

In addition, the main reason for the failure of the sand pump is that the drilling fluid containing mud and sand easily enters the stuffing box, causing severe wear on the shaft sleeve. The mechanical seal is a sealing device composed of one or several pairs of rotating and stationary rings. It relies on the pressure of the elastic element and the sealing medium to generate appropriate compression force on the rotating and stationary ring end faces to make them fit closely, thereby maintaining a very thin liquid film to achieve the purpose of sealing. The mechanical seals used on sand pumps usually have a lifespan of only 5-6 months. The sealing surface of the sand pump shaft seal in drilling fluid quickly wears out and fails completely.

There could be multiple reasons: improper lubrication management, internal springs obstructed by sand particles leading to ineffective movement of the rotating ring, pump body vibration, and so on.

The reliability of the sand pump equipment directly affects the performance of the drilling fluid desander and desilter, and thus affects the normal operation of the entire drilling solid control system. The sand pump used on the drilling site is a horizontal sand pump, and the failure of the horizontal sand pump is caused by the seal. The characteristics of the packing seal are simple structure but short lifespan, usually requiring packing addition once a day. At the same time, it is difficult to control the tightness of the packing. If it is too tight, the shaft power increases, the packing heats up, and it is easy to burn the packing and shaft sleeve. If it is too loose, it does not seal properly, leading to mud leakage.